Projects Overview A6/III Strengthening of structures subjected to normal forces against an impact load transverse to the normal force

A6/III Strengthening of structures subjected to normal forces against an impact load transverse to the normal force

Motivation

The investigation of structural elements that are preloaded by normal forces and subjected to impact load perpendicular to the normal force is no less relevant than the investigation of structural elements subjected to bending only investigated so far in A5 and A6. Elements subjected to normal forces are, for example, wall structures, skeleton structures, columns, but also pre-stressed structures. While in the previous cohorts the impact loading of (apart from the dead weight) unloaded components was investigated in A5/I, A5/II as well as in A6/II, in A6/III the combined loading of normal force loading in one direction and impact transverse to this normal force direction is to be investigated in more depth.

State of research and preliminary work

In the first two cohorts of the GRK, various materials and composites were investigated with regard to their performance in an impact event [SC1]. The spectrum ranges from small-scale material tests (primarily in projects A1-A4) to component tests (primarily in projects A5 and A6). Investigating steel-reinforced concrete (RC) slabs in projects A5 and A6, an explicit distinction was made as to whether a strengthening layer was applied on the impact-facing side [CU1] or on the rear side [CU2, SC2]. This was mainly due to the fact that both processes were initially to be analysed separately from each other. Material properties [CU3] as well as structures [CU4] were investigated. Strengthening on the impact-facing side and on the rear side, for both scenarios, suitable materials and strengthening solutions were found. Towards the end of the second cohort, additional investigations are planned on flat components with a damping layer on the impact-facing side facing side and a strengthening layer on the rear side.

But what design and construction solutions are needed when the direction of the impact cannot be predicted? In this case, a strengthening layer must have a damping effect and at the same time be able to absorb high tensile stresses. In addition, a simultaneously acting normal force in the impacted component influences its structural behaviour compared to the plates considered so far. For these general conditions described here, the solution needs to be found. This requires experiments in the laboratory as well as theoretical considerations in order to be able to represent the observed processes numerically and in an engineering model. The experimental investigations will be based on different measurement techniques [MA1-MA4].

Scientific task and project goals

The research in A6/III will include experiments in the laboratory as well as theoretical considerations in order to be able to represent the observed processes numerically and in an engineering model. In order to achieve the goal for the A6/III project, the following sub-questions and sub-objectives are to be addressed:

- Selection of suitable materials: Since the direction of an impact cannot be assumed to be known, a strengthening layer of a structure predominantly subjected to normal-force (e.g. a column in a skeleton structure) must have both, strengthening and energy-absorbing properties. Corresponding strengthening solutions are to be developed, based on the results of the A-projects of cohorts I and II.

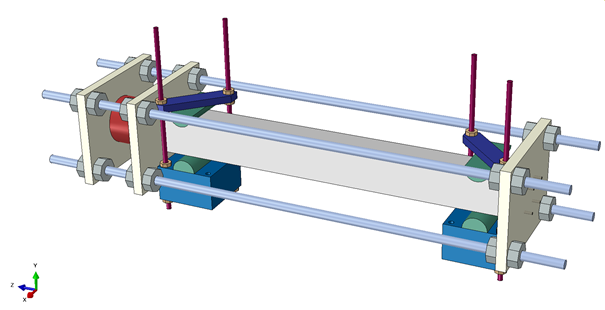

- Analysis of the behaviour of strengthened members: Possibilities and potential of strengthening measures on the impact-facing side and on the rear side are explored experimentally and through accompanying simulations. For this purpose, a suitable test set-up including the recording of measured values must be developed, with which both the static normal force and the horizontal impact load can be introduced in a test specimen at the same time. In addition to the obligatory small-scale tests for material characterisation, large-scale tests on unstrengthened and strengthened components are planned. The number of variations will be determined based on the theoretical preliminary considerations with which the mode of action of different reinforcement layers is to be estimated.

- Development of an engineering design model: The knowledge gained is combined and transferred into an engineering model.

Interaction with other projects of Cohort III

A close interaction is planned with project A1. This focusses on specific strengthening reinforcement such as 3D-textiles and wrapping textiles. Regarding simulation of interaction of normal load and transverse impact load, a close cooperation with project B1 is planned. Close interaction is also planned with C1 in questions of measurement of damage and imaging techniques. Close interaction is also planned with project A5 regarding the drop tower tests. Ongoing interaction of cohort II with A3 (SHH-Matrix) is to be continued.

Literature

[CU1] Bracklow, F.: Rückseitige Verstärkung von Stahlbetonplatten unter Impaktbeanspruchung. In: Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach, Prof. Dr.-Ing. Steffen Marx, Prof. Dr.-Ing. Viktor Mechtcherine (Hrsg.): Beiträge zum 61. Forschungskolloquium mit 9. Jahrestagung des DAfStb : 26. / 27. September 2022 Technische Universität Dresden., 2022 – URL: https://doi.org/10.25368/2022.373

[CU2] Leicht, L.: Charakterisierung von mineralisch gebundenen Kompositen zur Impaktdämpfung. In: Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach, Prof. Dr.-Ing. Steffen Marx, Prof. Dr.-Ing. Viktor Mechtcherine (Hrsg.): Beiträge zum 61. Forschungskolloquium mit 9. Jahrestagung des DAfStb : 26. / 27. September 2022 Technische Universität Dresden., 2022 – URL: https://doi.org/10.25368/2022.372

[CU3] Leicht, L.; Fíla, T.; Maca, P.; Curbach M.: Dynamic beam-end tests: Investigation using split Hopkinson bar. International Journal of Impact Engineering (2022) – DOI: 10.1016/j.ijimpeng.2022.104417

[CU4] Leicht, L.; Máca, P.; Beckmann, B.; Curbach, M.: Geometric influences on the behaviour of beams under impact loading. In: Proc. of 26th Int. Conf. of Structural Mechanics in Reactor Technology (SMiRT 26). 10.-15.07.2022 in Potsdam (Germany), 2022

[SC1] Hering, M.; Scheerer, S.; Curbach, M.; Vo, D. M, P.; Sennewald, C.; Cherif, C.; Liebold, F.; Maas, H.-G.; Qinami, A.; Steinke, Chr.; Fuchs, A.; Kaliske, M.; Curosu, I.; Mechtcherine, V.: Impaktsicherheit von Baukonstruktionen durch mineralisch gebundene Komposite: Bauteilebene. Beton- und Stahlbetonbau 116 (2021) 1, S. 58-67 – DOI: 10.1002/best.202000067

[SC2] Hering, M.; Bracklow, F.; Scheerer, S.; Curbach, M.: Reinforced Concrete Plates under Impact Load – Damage Quantification. Materials, Special Issue “Mineral-Bonded Composites for Enhanced Structural Impact Safety” 13 (2020) 20, 4554, 13 S. – DOI: https://doi.org/10.3390/ma13204554

[MA1] Katarzyna Zdanowicz; Daniel Gebauer; Marc Koschemann an Kerstin Speck; Oliver Steinbock; Birgit Beckmann; Steffen Marx: Distributed fibre optic sensors for measuring strains of concrete, steel and textile reinforcement: possible fields of application. Structural Concrete (2022), S. published online – DOI: 10.1002/suco.202100689

[MA2] Käding, M.; Schacht, G.; Marx, S.: Acoustic Emission analysis of a comprehensive database of wire breaks in prestressed concrete girders. Engineering Structures 270 (2022), 114846

[MA3] Zdanowicz, K.; Marx, S.: Flexural behaviour of thin textile reinforced concrete slabs enhanced by chemical prestressing. Engineering Structures 256 (2022), 113946

[MA4] Kang, C.; Schneider, S.; Wenner, M.; Marx, S.: Experimental investigation on the fatigue behaviour of rails in the transverse direction. Construction and Building Materials 272 (2021) 121666, S. 1-14

Contributors

© Dominik Junger

Doctoral Researcher

GHAZALEH TAHERI, M.SC.

Institute of Concrete Structures

Technische Universität Dresden,

ABS, Room 07-030b

August-Bebel-Straße 30/30A

01219 Dresden

Germany

- ghazaleh.taheri@tu-dresden.de

- +49 351 463 40474

- +49 351 463 37289

Principal Investigator

Univ.-Prof. Dr.-Ing. Steffen Marx

Institute for Photogrammetry and Remote Sensing

Helmholtzstraße 10

01069 Dresden

Germany

- steffen.marx1@tu-dresden.de

- Institute

- +49 351 463 35856

- +49 351 463-37289

Principal Investigator

Dr.-Ing. Silke Scheerer

Institute of concrete structures

ABS, Floor 05, Room 012

August-Bebel-Straße 30/30A

01219 Dresden

Germany

- Silke.Scheerer@tu-dresden.de

- Institute

- +49 351 463 36527

- +49 351 463 37289

in cooperation with

Prof. Dr.-Ing. Stefan Löhnert

Institute of Mechanics and Shell Structures

TU Dresden, Faculty of Civil Engineering, 3rd floor, room 03-017

August-Bebel-Straße 30

01219 Dresden

Germany

- stefan.loehnert@tu-dresden.de

- Institute

- +49 351 463 43231

- +49 351 463 43235

in cooperation with

Univ.-Prof. Dr.-Ing. habil. Dipl.-Wirt. Ing. Chokri Cherif

Institute of Textile Machinery and High

Performance Material Technology (ITM)

Hohe Straße 6, Room 138

01069 Dresden

Germany

- chokri.cherif@tu-dresden.de

- Institute

- +49 351 463 39300

- +49 351 463 39301